Change language

Welcome to your strong partner for tool presetting, shrinking equipment, training, repair and calibration.

May I introduce myself?

The tool being in all facets in industrial manufacturing environments is the focus of my career and vocation at the same time. That you feel it as a customer from the first contact, transmitted during the execution of the works, as well as the follow-up.

A proper documentation is a matter of course for me. Fast response times and short-term appointments - you can count.

And you always have to do with the "boss"! Since there is no ambiguity or misunderstanding.

What may I do for you?

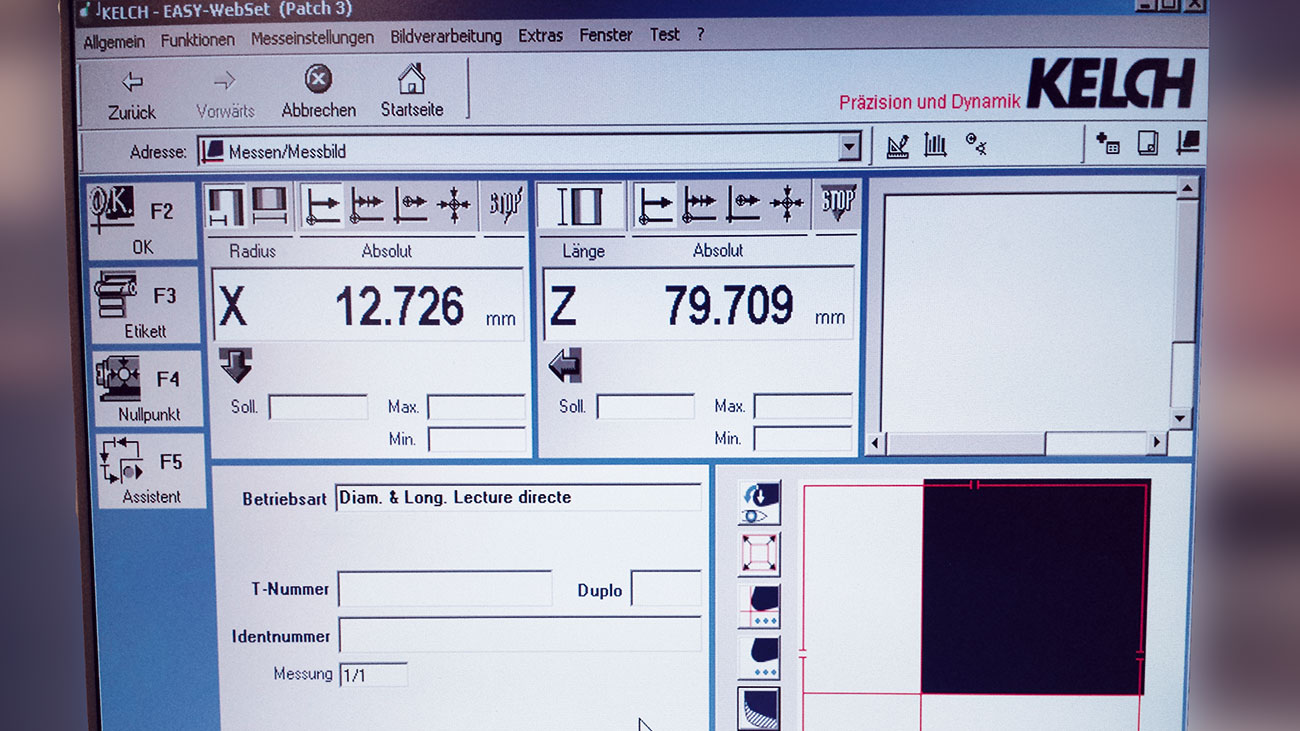

- Maintenance, calibration and preventive maintenance of tool presetting

- Maintenance and preventive maintenance of their shrinking devices

- Repairs

- Commissioning of equipment

- Internal relocation of tool presetting and shrinking devices

- Training and instruction of the operator

- Programming and optimization of measuring programs with customer tools on site

- Lenses and expert advice on new purchases from a technical and economic perspective

- Cheap used equipment available on request

Or do you need support in your tool presetting, as employees short or long-term failure? Because your orders and customers can not wait. After consultation I submit willingly to include an offer to the bottleneck in your production.

What do you gain?

- Attractive price/performance ratio

- Fast response times, thereby decreasing downtime

- Many years of experience in industry and technology

- Precise adjustment results your Precision Tools

- Vendor independence

- Working world

Getting in touch:

About the inquiry form you have the option to request a quote. In addition, please contact us at the contact information listed.

I look forward to a long-term, trusting and successful cooperation.

Tool presetting

- Repairs to your tool presetting different manufacturers (Kelch, Zoller, PWB, others on request)

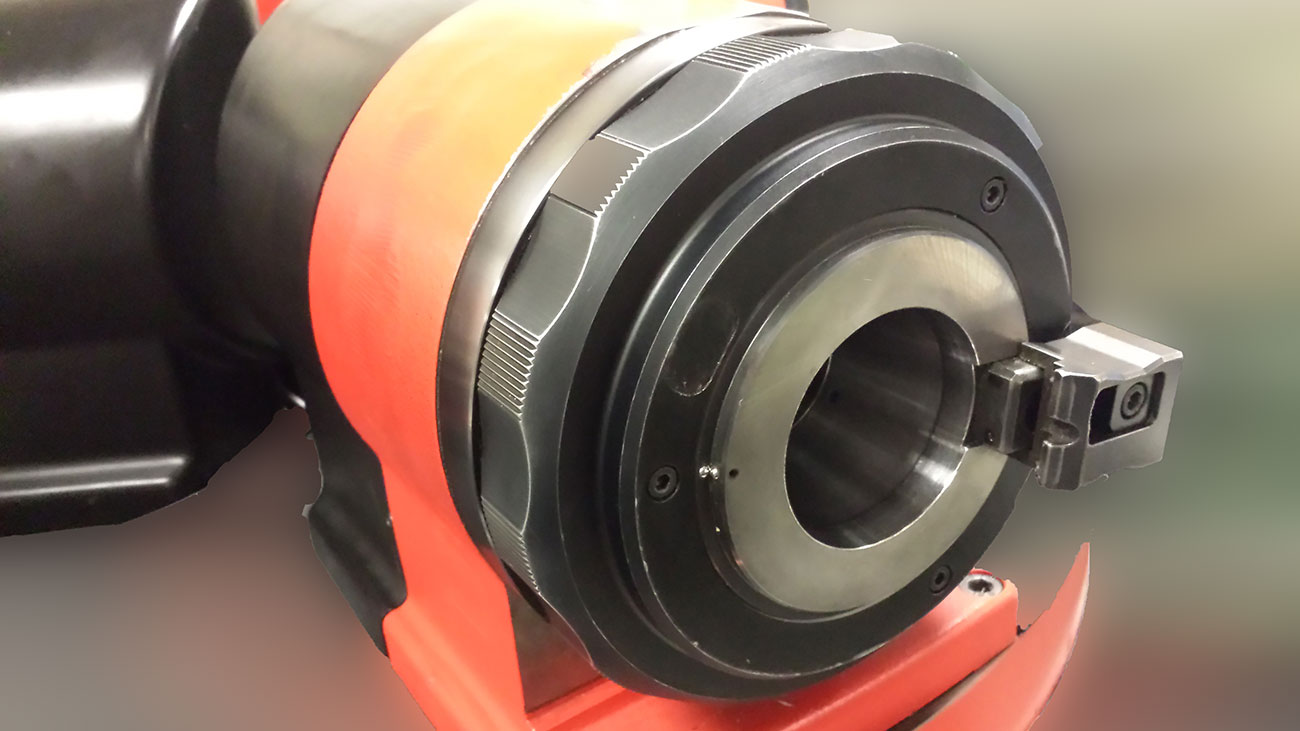

- Overhaul your rotation spindles of HSK and SK - series of your tool presetting

- Spare Parts Service

- Toolholders HSK DIN 69893/ISO 12164

- Mill holder DIN 6359 with cooling channel for parallel DIN 1835 - B (Weldon)

Maintenance and calibration

- Maintenance, and calibration of your tool presetting preventive Instadhaltung

- Extensive contemporary checklists in paper form and/or as a .pdf file

- Maintenance contracts

- Calibration Service for your concentricity test mandrels and calibration gauges

Shrink equipment

- Maintenance and preventive maintenance of your equipment Shrink

- Repair at present faults and defects

- Shrink chuck for mounting of cylindrical HSS and solid carbide tool shanks

Training

- Training and instruction of your personnel at various setting devices, digital readouts, controllers and software